Презентация продукции

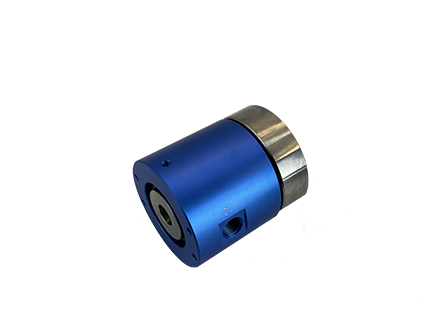

Reehonde последние инновации Пневматический роторный союзЭто высокоточное инженерное решение, предназначенное для удовлетворения жестких требований различных промышленных применений. Этот многофункциональный продукт сочетает в себе пневматические и электрические соединения в компактном блоке, обеспечивая плавное вращение при сохранении высокой производительности.

В Пневматический роторный союз предназначен для сред, в которых жидкие и электрические сигналы должны передаваться непрерывно через вращающиеся интерфейсы. Его передовая конструкция интегрирует высококачественные материалы и точные методы производства, что делает его идеальным выбором для систем, требующих надежной и эффективной работы.

Параметры продукта

Трудовая жизнь | Таблица классификации продукции | Номинальное напряжение | 0-440VACNDC |

Номинальная скорость | Таблица классификации продукции | Сопротивление изоляции | <500mq> |

Рабочая температура | -30°C~80°C | Спецификация провода | AWG17#/AWG22#Тефлон с серебряным покрытием |

Рабочая влажность | 0 ~ 85% Относительная влажность | Длина провода | Стандартная длина 250 мм |

Контактный материал | Таблица классификации продукции | Изоляционная прочность | 500VAC@50XHz и 6S |

Материал оболочки | Алюминиевый сплав | Значение изменения динамического сопротивления | <0.010<> |

Rotation torque | 0.05N.m+0.02N.m/6Flow passage | Protection level | IP51 |

Product Features

Durable Construction

Shell Material: Constructed from lightweight yet durable Алюминиевый сплав, the Пневматический роторный союз offers excellent corrosion resistance and mechanical strength.

Contact Material: Таблица классификации продукции for specific contact materials tailored to suit your application's needs, ensuring optimal electrical conductivity and wear resistance.

Versatile Performance

Rated Voltage: Supports a wide range of voltages from 0 to 440VAC/DC, making it compatible with various electrical systems.

Rated Speed: Таблица классификации продукции for speed ratings tailored to your specific requirements, ensuring smooth and reliable operation at high speeds.

Robust Insulation

Insulation Resistance: Less than 500MΩ at 300VDC, ensuring high electrical isolation and safety.

Insulation Strength: 500VAC at 50Hz for 6 seconds, providing additional safety margin against electrical breakdown.

Wide Operating Range

Working Temperature: Rated for temperatures ranging from -30°C to 80°C, allowing for use in a variety of environmental conditions.

Working Humidity: Suitable for operating humidity levels up to 85%RH, ensuring performance in humid environments.

High-Quality Wiring

Wire Specification: AWG17#/AWG22# Silver-coated Teflon wires, offering excellent electrical conductivity and resistance to heat and chemicals.

Wire Length: Standard length of 250mm, customizable to fit your specific application needs.

Smooth Rotation

Rotation Torque: Low torque of 0.05N.m + 0.02N.m/6 rotations, ensuring minimal friction and wear during operation.

Dynamic Resistance Change Value: Less than 0.010, maintaining consistent electrical performance throughout the rotation.

Pneumatic Connectivity

Flow Passage: Designed with multiple flow passages to accommodate pneumatic requirements, ensuring smooth and uninterrupted fluid transfer.

Protection Level

Protection Level: IP51 rated, providing a degree of protection against solid objects and dripping water, ensuring reliability in harsh environments.

Application Areas

В Пневматический роторный союз is versatile and can be utilized in a wide range of industrial applications, including but not limited to:

Automation Systems: Ideal for robotic arms and automated machinery where both electrical signals and pneumatic power need to be transmitted through rotating joints.

CNC Machines: Provides seamless integration for tools and sensors that require continuous electrical and pneumatic connections during machining operations.

Medical Equipment: Suitable for medical robots and patient-handling systems requiring precise and reliable pneumatic and electrical connections.

Aerospace and Defense: Utilized in gimbal systems, radar antennas, and other rotating components where high reliability and performance are critical.

Packaging Machinery: Ensures smooth operation of conveyors, indexing systems, and other packaging equipment that rely on both electrical and pneumatic control.

Installation Method

Installing the Пневматический роторный союз is a straightforward process that requires attention to detail to ensure optimal performance. Follow these steps for a successful installation:

Preparation:

Ensure all necessary tools and materials are available, including screws, seals, and mounting hardware.

Clean the installation area to remove any dirt, debris, or contaminants that could affect performance.

Mounting:

Position the Пневматический роторный союз on the desired mounting surface, aligning it with the rotating shaft and fluid/electrical connections.

Secure the union using the provided mounting hardware, ensuring it is tightly fastened to prevent leakage or movement during operation.

Wiring:

Connect the electrical wires to the corresponding terminals on the Пневматический роторный союз, following the wiring diagram provided.

Use wire connectors or soldering to ensure secure and reliable connections.

Apply heatshrink or electrical tape to protect the connections and prevent short circuits.

Pneumatic Connections:

Attach the pneumatic tubing to the flow passages on the Пневматический роторный союз, using appropriate fittings and seals to prevent leaks.

Ensure that all connections are tight and secure, and test the pneumatic system for leaks before operating.

Testing:

Before full-scale operation, perform a functional test to verify that the Пневматический роторный союз is working correctly.

Check for any leaks, electrical shorts, or unusual noise that may indicate a problem.

Adjust and fine-tune as necessary to ensure optimal performance.

FAQ

Q: What is the maximum operating pressure for the Пневматический роторный союз?

A: В maximum operating pressure depends on the specific model and configuration of the Пневматический роторный союз. Please refer to the product grade selection table or consult our technical support team for detailed information.

Q: Can the Пневматический роторный союз be customized to fit my specific application?

A: Absolutely! At Reehonde, we offer customized solutions to meet the unique needs of our customers. Our team of engineers can work with you to design a Пневматический роторный союз tailored to your specific application requirements.

Q: How do I maintain the Пневматический роторный союз to ensure long-term performance?

A: Regular maintenance is key to ensuring the long-term performance of the Пневматический роторный союз. Inspect the unit regularly for signs of wear, corrosion, or damage. Clean and lubricate the rotating components as needed, and replace worn-out parts promptly. Additionally, keep the Пневматический роторный союз protected from extreme temperatures, moisture, and contaminants to extend its lifespan.

Q: Is the Пневматический роторный союз compatible with all types of fluids?

A: В Пневматический роторный союз is designed to be compatible with a wide range of fluids, including air, water, oils, and other non-corrosive liquids. However, it is important to consult the product specifications and material compatibility chart to ensure that the Пневматический роторный союз is suitable for your specific fluid application.

Q: Can I install the Пневматический роторный союз in any orientation?

A: В Пневматический роторный союз can be installed in various orientations, depending on the specific model and application requirements. However, it is important to follow the installation instructions and guidelines provided to ensure proper alignment and function. Contact our technical support team if you have any questions about the appropriate installation orientation for your application.

Q: What is the warranty period for the Пневматический роторный союз?

A: Reehonde offers a comprehensive warranty for our Пневматический роторный союз, covering defects in materials and workmanship. В specific warranty period depends on the product model and purchase date. Please refer to the warranty statement provided with your product or contact our customer service team for more information.